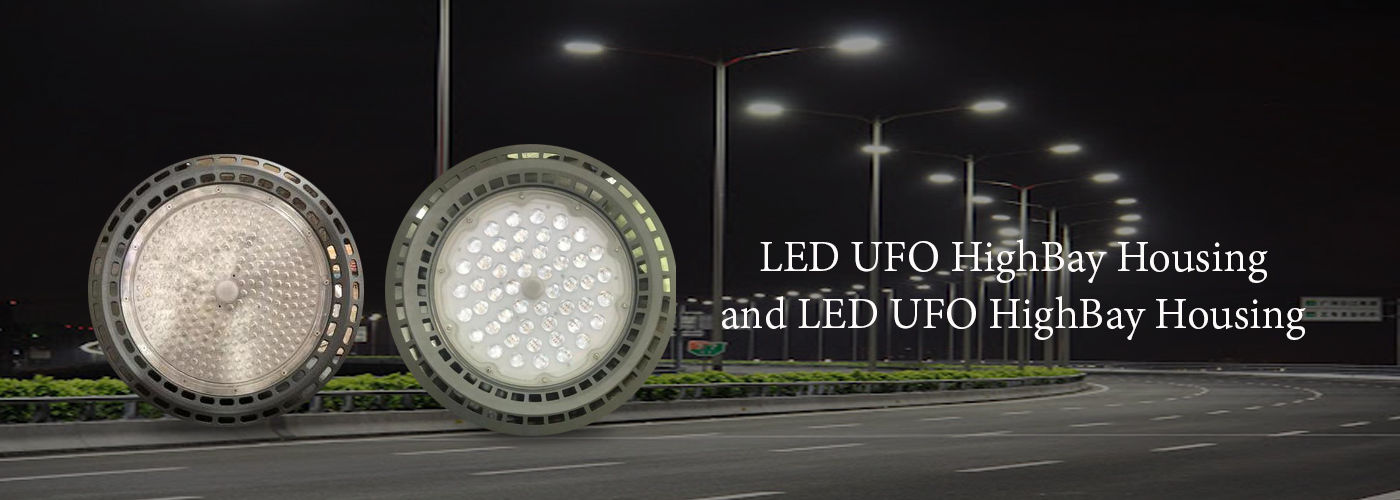

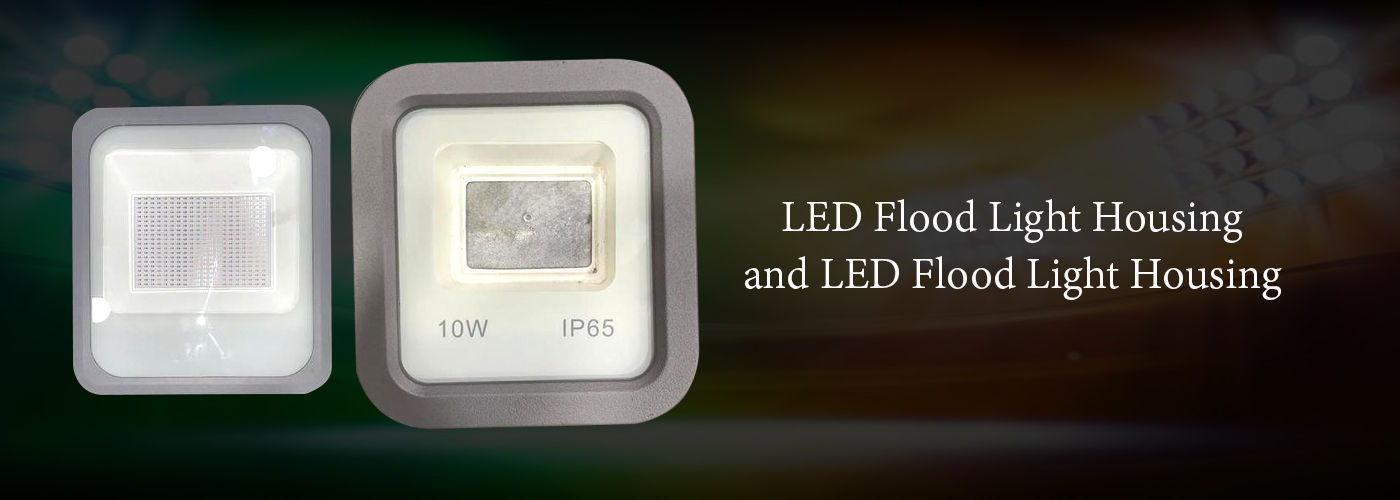

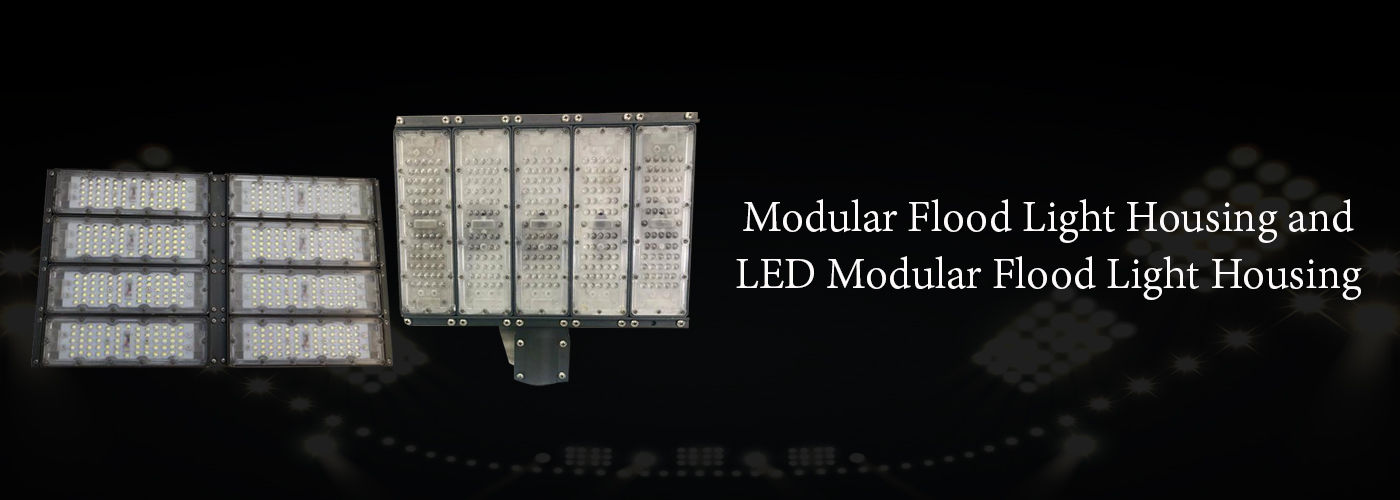

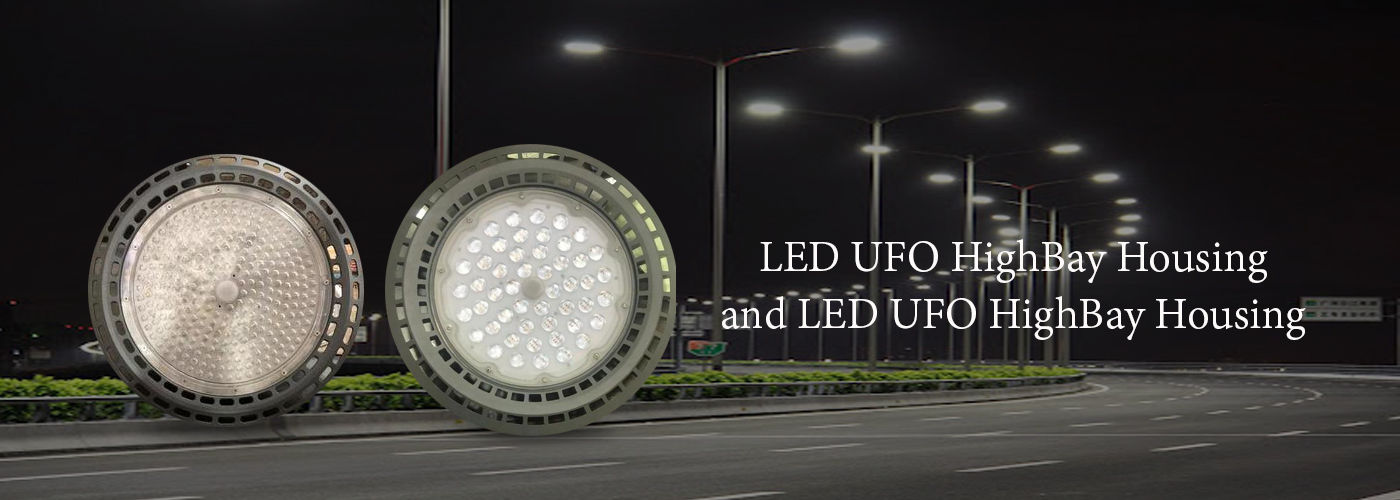

Offering a premium range of LED Street Light Housing, Pressure Die Casting Components, CNC Turning Components, Aluminium & Zinc Pressure Die Casting Components, etc.

Company Overview

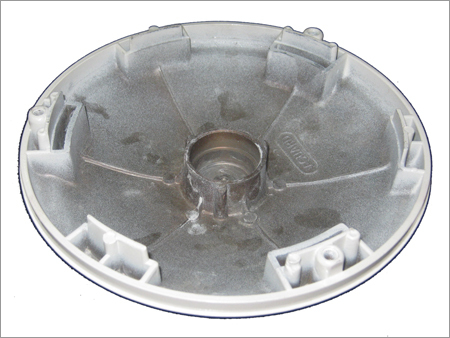

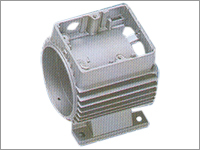

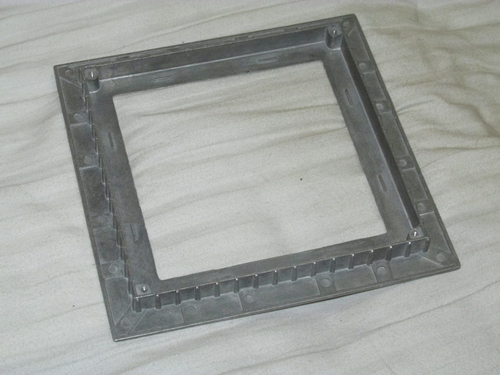

For more than 4 decades, Seva Die Casting has been in the service of customers dispersed across many industries such as electrical appliances, auto parts industries and several other industries. We are a trusted name for all kinds of Die Casting Components. As a reputed manufacturer, exporter and supplier, we offer precision made Pressure Die Casting Components, CNC Turning Components, and more.

Client Satisfaction

Being a highly customer centric organisation, we work with the belief that complete customer satisfaction can be attained by continuously upholding our high standards of quality in our array of Pressure Die Casting Components, CNC Turning Components, Aluminum & Zinc Pressure Die Casting Components, etc. All the products that we offer to our customers are manufactured upto the latest standards of the Die Casting industry. We have a strict quality control policy that is followed by all our team members. Our team is composed of extremely talented individuals with a deep insight in the field, which enables us to meet the requirements of our customers in an organized and timely manner. Further, we believe that customer feedback is one of the most important assets of the organisation, we understand their requirements and serve them accordingly. The superior quality of our products have enabled them to find a vast market in countries like Thailand, UAE, Australia and Kenya.

Infrastructure Base

To facilitate a smooth and undisturbed operation of our business, we have established a sophisticated infrastructural base which functions under the supervision of our skilled workers and experts owning immense expertise of the vertical. Further, we have also employes advanced CNC turning machines to support our equipment to produce premium quality Die Castings. All the necessary modern resources are provided to the workers to ensure the efficiency of our facility to constantly meet print specification requests of our clients. In future, our goal is to expand this base even further to enhance our productivity.

|

SEVA DIE CASTING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS